What is Brown Fused Alumina?

Brown fused alumina takes the high quality bauxite as the raw material, mixing with iron powder and anthracite, produced by melting in the electric arc furnace at a high temperature over 2000°C.

Main chemical compositions are Al2O3, TiO2, and small amount of SiO2 and Fe2O3 etc. Toughness is higher than SiC. It has features of good crystallization, high hardness, low linear expansion coefficient and corrosion resistance.

Main Colors

- Brown

Price

USD $0.78-1.97 / kg EXW

Packaging

25 kg bags or customized packaging on request

Physical Properties

| Item | Value |

|---|---|

| Appearance | White granular |

| Crystal | Trigonal Crystal |

| Bulk Density | 1.95g/cm3 |

| True Density | ≥3.9g/cm3 |

| Mohs Hardness | 9.0 |

| Melting point | 2250°C |

| Refractory Degree | 1900°C |

| Molecular formula | Al2O3 |

| Al2O3 CAS No. | 1344-28-1 |

| HS Code | 2818101000 |

Chemical Composition(%)

| Model | Particle Size | Al2O3 | TiO2 | CaO | SiO2 | Fe2O3 |

|---|---|---|---|---|---|---|

| BFA | F4-F24 | ≥95.50 | ≤3.40 | ≤0.42 | ≤1.00 | ≤0.25 |

| F30-F80 | ≥95.00 | ≤3.40 | ≤0.42 | ≤1.00 | ≤0.25 | |

| F90-F150 | ≥94.50 | ≤3.40 | ≤0.42 | ≤1.00 | ≤0.25 | |

| F180-F220 | ≥94.00 | ≤3.60 | ≤0.45 | ≤1.00 | ≤0.25 |

Advantages

- High purity, good crystallization, strong fluidity

- Small crystal size, impact resistance

- Shaping grade particles are ideal for wet blasting and polishing abrasives

- Can be processed according to user requirements

Applications

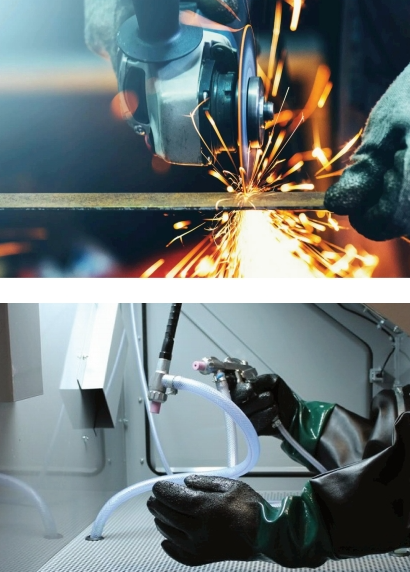

- F-grit for bonded abrasives such as resin bonded grinding wheels, vitrified grinding wheels.

- P-grit for coated abrasives such as sandpaper, sanding belts.

- Blasting media, metal preparation.

- Laminates, coatings, lapping, polishing.

- Anti-slip applications like floor, ceramics, auto brake parts.

- Manufacturing advanced refractory materials, castables, refractory bricks, etc.