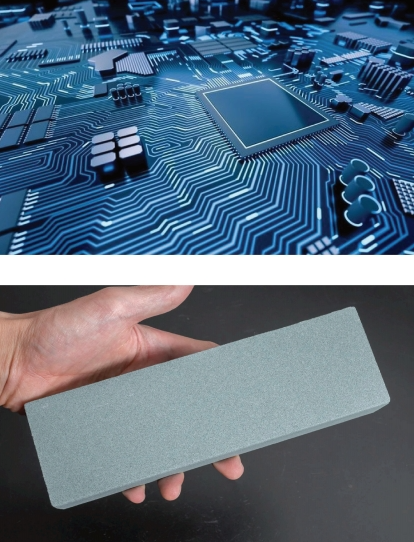

What is Green Silicon Carbide?

Green silicon carbide takes petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and is smelted through a resistant furnace at high temperature.

Its hardness is between corundum and diamond, the mechanical strength is higher than corundum, brittle and sharp.

Main Colors

- Green

Price

USD $2.69-4.66 / kg EXW

Packaging

25 kg bags or customized packaging on request

Physical Properties

| Item | Value |

|---|---|

| Appearance | Green powder |

| Mohs Hardness | 9.2 |

| Basic Mineral | α-SiC |

| True density | ≥3.90g/cm3 |

| Bulk density | 1.2-1.6g/cm3 |

| Crystal | Hexagonal |

| SIC CAS No. | 409-21-2 |

| HS Code | 2849200000 |

Chemical Composition(%)

| Model | Particle Size | SiC | F.C. | Fe₂O₃ |

|---|---|---|---|---|

| GC | F230–F280 (#240–#360) | ≥98.40 | ≤0.20 | ≤0.25 |

| F320–F500 (#400–#800) | ≥98.20 | ≤0.20 | ≤0.30 | |

| F600–F800 (#1000–#1500) | ≥98.00 | ≤0.20 | ≤0.30 | |

| F1000–F1200 (#2000–#2500) | ≥97.60 | ≤0.20 | ≤0.30 | |

| #3000–#8000 | ≥96.50 | ≤0.20 | ≤0.30 | |

| #10000–#20000 | ≥96.00 | ≤0.20 | ≤0.30 |

Particle Distribution(μm)

| Particle Size | D0 | D3 | D50 | D94 |

|---|---|---|---|---|

| #240 | ≤127 | ≤103 | 58.6±3.0 | ≥40.0 |

| #280 | ≤112 | ≤87.0 | 49.4±3.0 | ≥33.0 |

| #320 | ≤98.0 | ≤74.0 | 41.1±2.5 | ≥27.0 |

| #360 | ≤86.0 | ≤66.0 | 36.1±2.0 | ≥23.0 |

| #400 | ≤75.0 | ≤58.0 | 30.9±2.0 | ≥20.0 |

| #500 | ≤63.0 | ≤50.0 | 26.4±2.0 | ≥16.0 |

| #600 | ≤53.0 | ≤43.0 | 21.1±1.5 | ≥13.0 |

| #700 | ≤45.0 | ≤37.0 | 17.9±1.3 | ≥11.0 |

| #800 | ≤38.0 | ≤31.0 | 14.7±1.0 | ≥9.00 |

| #1000 | ≤32.0 | ≤27.0 | 11.9±1.0 | ≥7.00 |

| #1200 | ≤27.0 | ≤23.0 | 9.90±0.80 | ≥5.50 |

| #1500 | ≤23.0 | ≤20.0 | 8.40±0.60 | ≥4.50 |

| #2000 | ≤19.0 | ≤17.0 | 6.90±0.60 | ≥4.00 |

| #2500 | ≤16.0 | ≤14.0 | 5.60±0.50 | ≥3.00 |

| #3000 | ≤13.0 | ≤11.0 | 4.00±0.50 | ≥2.00 |

| #4000 | ≤11.0 | ≤8.00 | 3.00±0.40 | ≥1.30 |

| #6000 | ≤8.00 | ≤5.00 | 2.00±0.40 | ≥0.80 |

| #8000 | ≤6.00 | ≤3.50 | 1.20±0.30 | ≥0.60 |

| #10000 | — | — | 0.51–0.70 | — |

| #20000 | — | — | 0.50 | — |

Applications

- Cutting and grinding of solar silicon wafers, semiconductor silicon wafers, and quartz chips.

- Polishing crystal, solid grain iron.

- Precision polishing and sandblasting of ceramics and special steel.

- Consolidated and coated abrasives.

- Grinding non-metallic materials such as glass, stone, agate and high-end jewelry and jade.

- Manufacture advanced refractory materials, engineering ceramics, heating elements and thermal energy elements, etc.